You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dovo manufacturing video

- Thread starter antdad

- Start Date

- Messages

- 672

That's an excellent video antdad, thanks for posting it! I only wish I spoke german! It has cleared-up some of the questions I had about the process, particularly the grinding and acid-etching. The double wet grinder is a brilliant piece of kit - I have seen a double belt-grinder rigged to do the same work, but cooling the blade so as not to lose the temper was an issue - the maker of the double belt grinder puts his blades in dry ice (he is known as the "iceman") to achieve the same ends. The Dovo machine looks far more efficient, and so it should, probably based on an ancient machine that has hardly changed.

I noticed a workman banging the odd blade after stamping and the initial heat treatment - presumably because the blades had warped a little due to internal stresses. This seems to be a problem - a lot of people remark that their new razor is warped straight from the factory.

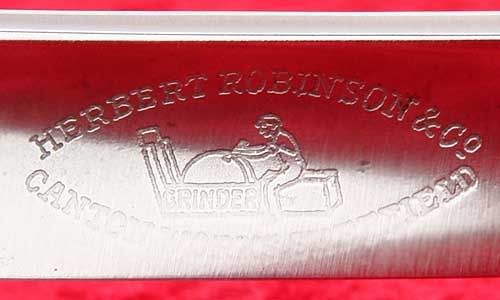

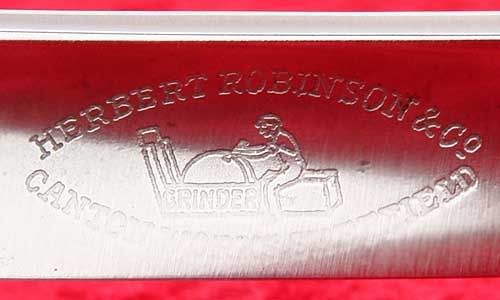

Another machine that looks just the same as those pictured in old 1900 and earlier drawings from Sheffield is the grinder/polisher used by the fellow sitting astride his machine. The big old Sheffield machines used a lead-lining on the wheel, and the compounds were pushed into the lead - the poor men sitting astride the machines with their faces inches from them (possible where the saying "nose to the grindstone" came from) didn't live long - if they survived potential accidents with the mechanism, they succumbed to breathing in the lead and dust. Here's a engraving from an old Sheffield balde:

The acid etching bit was very informative - to make the pattern the blade is painted with a resist, then dunked in the elctrolyte. Where the acid bites a satin finish is obtained. Looks like they missed out a few steps - I don't think that gold plates onto steel, the steel has to be plated with nickel first, and/or copper, possibly. Either that, or polarities are changed after a while so the blade material is taken off first, then the gold in the electrolyte is deposited.

Re: sharpening the edge, In the other forums I have visited the general opinion is that the spine of the razor is raised so as not to abrade the spine, but it didn't look like it in this video. Without some mechanical means of keeping the spine raised by a fixed amount I don't see how it could be done by hand and maintain the correct bevel at the edge. The final honing sequence was a bit of an eye-opener too - I wasn't expecting that back/forth movement!

Now I just need to find someone who can speak german...!

Regards,

Neil.

I noticed a workman banging the odd blade after stamping and the initial heat treatment - presumably because the blades had warped a little due to internal stresses. This seems to be a problem - a lot of people remark that their new razor is warped straight from the factory.

Another machine that looks just the same as those pictured in old 1900 and earlier drawings from Sheffield is the grinder/polisher used by the fellow sitting astride his machine. The big old Sheffield machines used a lead-lining on the wheel, and the compounds were pushed into the lead - the poor men sitting astride the machines with their faces inches from them (possible where the saying "nose to the grindstone" came from) didn't live long - if they survived potential accidents with the mechanism, they succumbed to breathing in the lead and dust. Here's a engraving from an old Sheffield balde:

The acid etching bit was very informative - to make the pattern the blade is painted with a resist, then dunked in the elctrolyte. Where the acid bites a satin finish is obtained. Looks like they missed out a few steps - I don't think that gold plates onto steel, the steel has to be plated with nickel first, and/or copper, possibly. Either that, or polarities are changed after a while so the blade material is taken off first, then the gold in the electrolyte is deposited.

Re: sharpening the edge, In the other forums I have visited the general opinion is that the spine of the razor is raised so as not to abrade the spine, but it didn't look like it in this video. Without some mechanical means of keeping the spine raised by a fixed amount I don't see how it could be done by hand and maintain the correct bevel at the edge. The final honing sequence was a bit of an eye-opener too - I wasn't expecting that back/forth movement!

Now I just need to find someone who can speak german...!

Regards,

Neil.

- Messages

- 726

Neil Miller said:The final honing sequence was a bit of an eye-opener too - I wasn't expecting that back/forth movement!

Me too. Compare that to this one from Mastro Livi.

[youtube]http://www.youtube.com/watch?v=wXkjXfuNbpg&feature=channel[/youtube]

- Messages

- 1,347

- Location

- sunny canvey in the Y-UK

Pete said:Neil Miller said:The final honing sequence was a bit of an eye-opener too - I wasn't expecting that back/forth movement!

Me too. Compare that to this one from Mastro Livi.

[youtube]http://www.youtube.com/watch?v=wXkjXfuNbpg&feature=channel[/youtube]

hey ive never honed a razor so i wouldnt know if this was right or wrong

- Messages

- 672

I don't suppose that right/wrong matters much if the end result is the same, and as Mastro (not Maestro as some US sites suggests - I don't think it's a title, just his name) Livi is quite legendary his results are exceptional. I do backhone a bit first on changing to a new stone, but not to the extent that he does - I believe it removes a microscopic burr. I was interested - and delighted - to see what appeared to be a white translucent Arkansas stone in his set. On SRD they all seem to slam these stones, but I have always thought they were very good - very slow, but very good, and have a part to play in a no-nonsense honing setup free from all the Norton/Chinese 12k/30k Shapton hyperbole and spin.

I haven't tried slapping a razor down on the strop like that either, though I've seen it done. I have tried the side of the palm honing trick when caught without a strop on holiday - it works, but it's a bit scary!

Regards,

Neil

I haven't tried slapping a razor down on the strop like that either, though I've seen it done. I have tried the side of the palm honing trick when caught without a strop on holiday - it works, but it's a bit scary!

Regards,

Neil

- Messages

- 672

I just found a link to the Iceman's webpage http://jmichaelphotography.com/icemandoublegrinder.htm that I mentioned in an earlier post - it concerns his double hollow grinding machine.

I reckon Colin could cobble together something like that.

I reckon Colin could cobble together something like that.

Using my unparallelled skill in A-level German, I pieced together what's going on in that first video. They're just explaining what you can see, mentioning how much time and concentration is needed in the preliminary stages of production, degree of heat required, that sort of thing.

It's really cool how blades are made. I didn't know how much work and how many people were involved.

It's really cool how blades are made. I didn't know how much work and how many people were involved.

- Messages

- 672

Unruhe - your german is at least useful! Most of mine comes from when I bought and sold german ww1 photos and deathcards. I can understand all the terms referring to assaults with deadly weapons, being gassed, being blown-up, sent to hospital, shot in the head/chest/heart, being machine-gunned, hit by shrapnel....etc, etc. Didn't help me one bit in Austria, though!

Regards,

Neil

Regards,

Neil